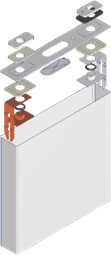

Current Collector(CC)

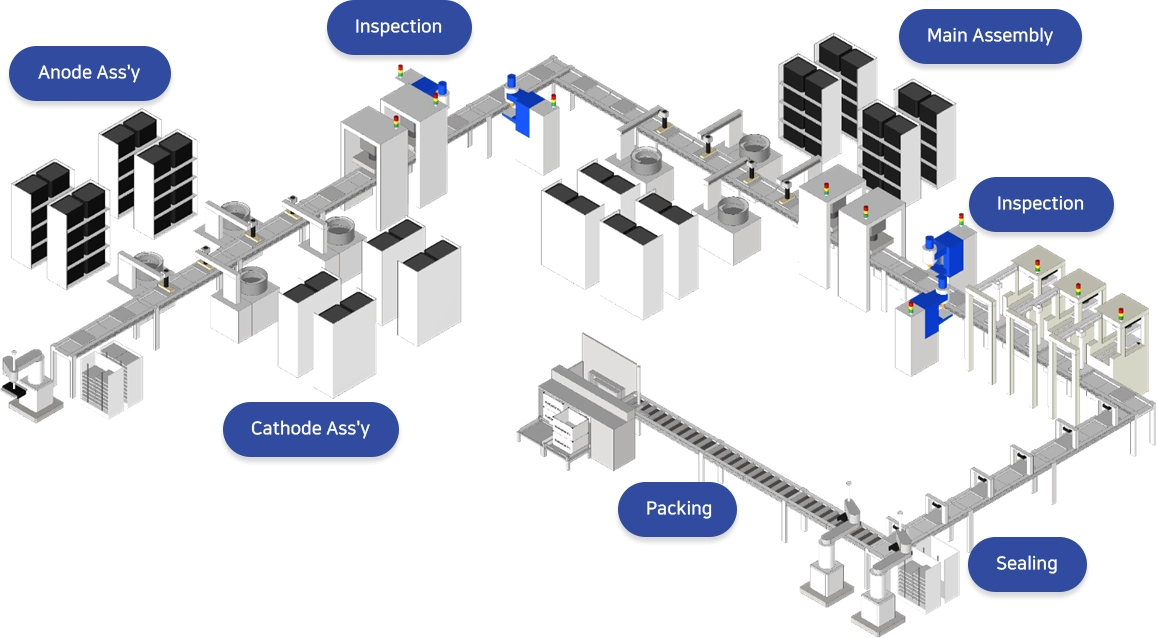

Process

- Parts supply

- Rivet caulking

- Laser welding

- Inspection

- Tray loading

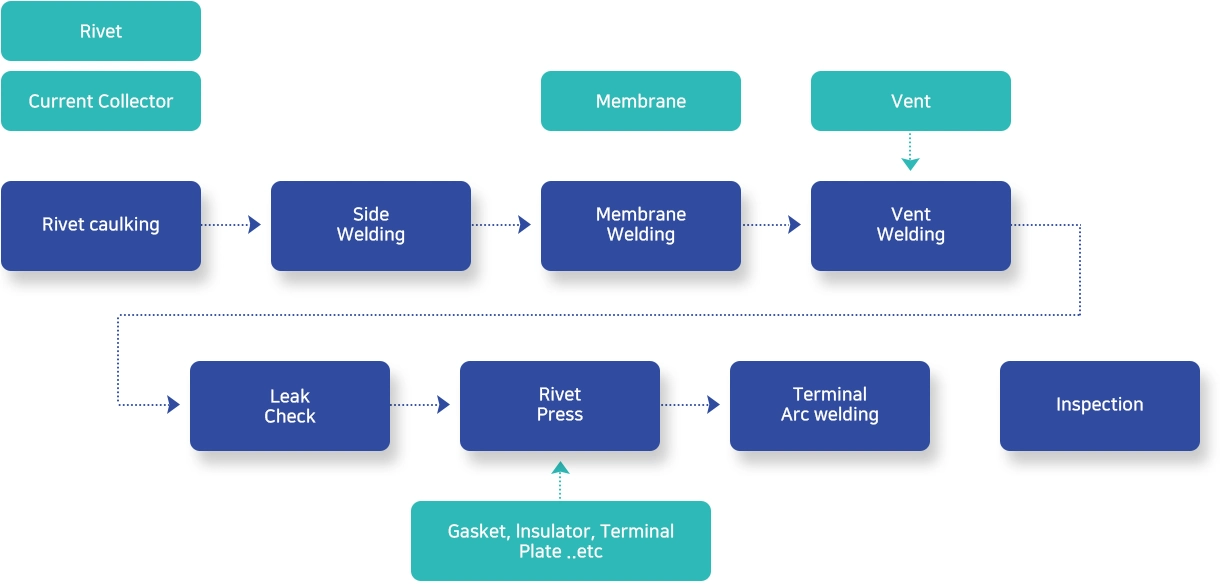

Can & Cap Assembly

BCC, running cap assembly line sub-component manufacturing is integrated, is demonstrating one-stop solution

for product design to development guaranteeing safety and quality.

The assembly line for this process is exhibited limitedly as in compliance to the technology protection law with the user,

and is separately configured according to the intended type and Ah of the line

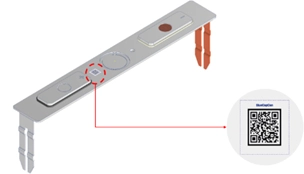

Short inspection,

Connection resistance test,

Flatness test, CC

disance/angle inspection,

Inspection for CP insert

Height, Terminal Height

inspection, CC side inspectio

In the battery production, Producing yield may be the most important factor and Bluecapcan has been accumulating manufacturing

technologies cooperating with lots of customers and keeps reliability and safety of our products.

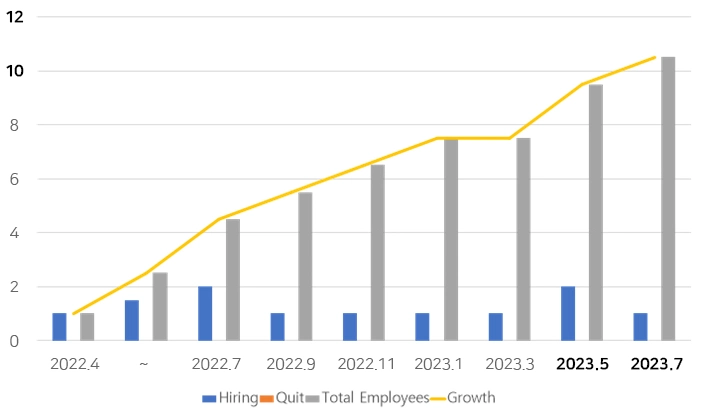

Employee has faith and passion to grow BCC

Get motivated on working and feel fun

No resignations there have been since joining BCC. BCC makes employees motivated to continue working in BCC by trying to become a GWP.

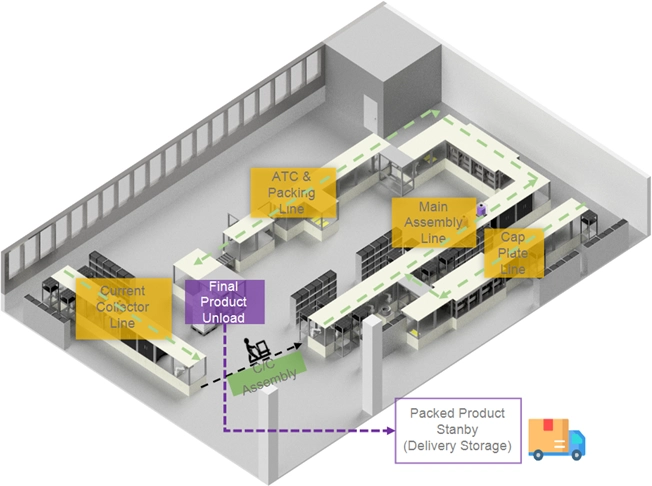

500 SQM facility required for pilot (1) line

Utility(EIectricityt Air. CIeaning water etc..) cost

Precise High-End automatic equipment line

ReguIarIy Maintenance (Mech/ControI)

lnitial Equipment setting (Local Site)

Measuring/Testing Devices

Least, 5 Operator / shift : 24M operating in a day (3 shift)

(Separate) Engineering Team

(Separate) QuaIity Team

(Separate) Delivery Team

R&D Cost (Different Prismatic Type)

Sales (Exhibition. Onsite meeting etc..)

Laser welding m/c 1 set (4KW)

Leak Test 1 set (CTS, SENTINEL C28)

Laser scanner 2 sets

Resistance measuring 1 set (HIOKI, BT3563)

OSD/Vent welding m/c 1 set

Short measuring 1 set (KIKUSUI, TOS5051A)

Riveting (Servo Press) 1 set

Zig & Pallet ( accordingly to Target model)

Circular welding m/c 1 set

Standard facility to test Vent durability Long-term reliability evaluation item setting to verify as to manage durability of components.

Components evaluation and inspection warranty are possible with the Standard equipment of leakage specializing leak inspection on sealing As the specification requested by customer.

Accurate and efficient evaluation of characteristic modes will be possible by building the standard of product models. standard test equipment specialized to all kinds of the durability and the cell components evaluation.

Strict quality management on both raw material and sub-component from partner companies

Standardized quality managing system on each process maintaining stable quality level

Set a one-stop quality management system from product designing, statistical management, measurement analysis, and potential impact analysis

In order to keep always manufacturing the best quality products, BCC controls quality in accordance with maintenance and preservation management standards

ISO9001/ISO14001/I-SO45001/IATF16949 certificated and managing system

본 사이트는

보안이 취약한 Internet Explorer 9 이하 버전을

지원하지 않습니다.

Internet Explorer 10 이상으로 업데이트 하거나

크롬, 파이어폭스 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.