Technology

CauIking & Riveting M/C

Welding M/C

Short Test M/C

Leak Test M/C

Breaking pressure & Vent LEAK test M/C

3D Measunng M/C

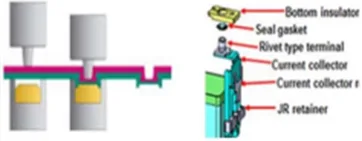

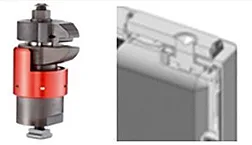

Research Area on Welding Technology and Assembly Design

BCC focuses on the cap assembly and can business utilized for medium and large-sized batteries,

and conducts technology development and research in accordance with the battery requirements needed in the industrial fields of prismatic, cylindrical, and side terminal cells.

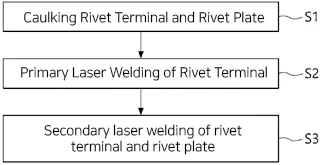

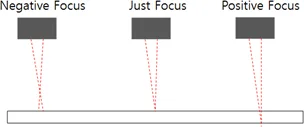

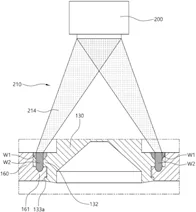

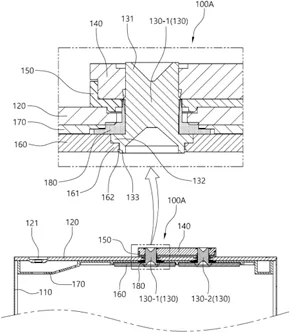

The technology to secure manufacturing efficiency and safety in intermetallic welding technology is evolving.

BCC has been applying metal welding utilizing laser beams based on continuous research and development to secure the core technology of bonding and welding between metals or dissimilar materials for manufacturing battery parts based on the experience and manufacturing technology

Lib Production machine

| ltem | Cathode | Anode |

|---|---|---|

| Active Material | NCM/LCP/LFP/LFMP/ Sodium ion | Graphite, C/Si-C/LTO |

| Binder | PVDF | SBR, CMC |

| Conductive Additives | as request | as request |

| Solvent | NMP | DI Water |

| Bare Foil Thickness | 10~20um | 4.5~12um |

| Coating Width | ~650mm | ~650mm |

| Single-side Coating Weight (without fOil) |

NCM/LCO: 6-30mg/㎠ LFP/LFMP: 6-20m ㎠ |

4.5-12mg/㎠ |

| CaIendering Width | ~ 400mm | ~ 400mm |

| CaIendering Thickness | ~ 150um | ~ 178um |

| Compaction Density | 2.2~2.4±0.05g/㎤ | 1.3~1.6土0.03g/㎤ |

Pouch Assembly Line - R&D

| Punching | Z-Stacking | Tab Welding | Forming | Side Sealing | Vacuum Sealing | Hot Pressing | |

|---|---|---|---|---|---|---|---|

| Cell Capa | 2-5 Ah (Cell Size should be equal for all the machines) | ||||||

| M/C Capa | 1~4 sheets/min | 6 sec/sheet | 2ppm | 2~4 sheets/min | 2ppm | 0.5~1ppm | 1~2ppm |

| Dimension (WxLxH) |

600x400x600 | 500x600x750 | 300x500x350 | 600x600x700 | 400x400x650 | 700x700x1,000 | 500x500x600 |

Pouch Assembly Line - Pilot

| Punching | Z-Stacking | Tab Welding | Forming | Sealing | El Filling | Degassing | Hot Pressing | |

|---|---|---|---|---|---|---|---|---|

| Cell Capa | 2-5 Ah (Cell Size should be equal for all the machines) | |||||||

| M/C Capa | 1~4 sheets/min | <0.2mm | 2ppm | <0.1mm | 2ppm | 0.5~1ppm | 0.5~1ppm | 1~2ppm |

| Dimension (WxLxH) |

2700x1000x2000 | 1550x1200x2000 | 1200x1100x2000 | 2100x1200x2000 | 1200x1600x2000 | 1200x1500x2000 | 900x1100x2000 | 800x800x2000 |

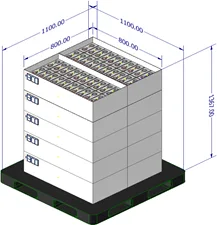

Cylindrical Assembly Line - Pilot

| Lead Tab Welding (+)/(-) |

Winding | (-) Tab Welding | Swaging | Beading | El Filling | (+) TAb Welding) | Crimping & Sizing | |

|---|---|---|---|---|---|---|---|---|

| Cell Capa | 18650/21700 (Machine to be compatible depending on cell model) | |||||||

| M/C Capa | 10 sec/pc | 50 sec/pc | 8 sec/cell | 15 sec/cell | 30 sec/cell | 3 min/cell | 15 sec/cell | 60 sec/cell |

| Dimension (WxLxH) |

800x700x1850 | 5000x2600x2400 | 800x800x2000 | 800x800x2000 | 800x800x2000 | 800x800x2000 | 1500x800x2000 | 1200x800x2000 |

본 사이트는

보안이 취약한 Internet Explorer 9 이하 버전을

지원하지 않습니다.

Internet Explorer 10 이상으로 업데이트 하거나

크롬, 파이어폭스 최신 브라우저를 이용해 주십시오.

불편을 드려 죄송합니다.